Everything About Industrial Scales: Secret Features and Advantages for Your Work Environment

Industrial scales are crucial in improving operational performance across numerous fields, using features such as high capacity, precision accuracy, and durable building. These instruments not just minimize human error however likewise assist in data assimilation and governing compliance, making them essential for quality control and material monitoring. As businesses progressively recognize the importance of these tools, the ramifications for efficiency and waste reduction become significantly significant. Recognizing the diverse types and applications of commercial scales can provide important understandings right into enhancing your office processes-- yet, the trip doesn't end there.

Types of Industrial Scales

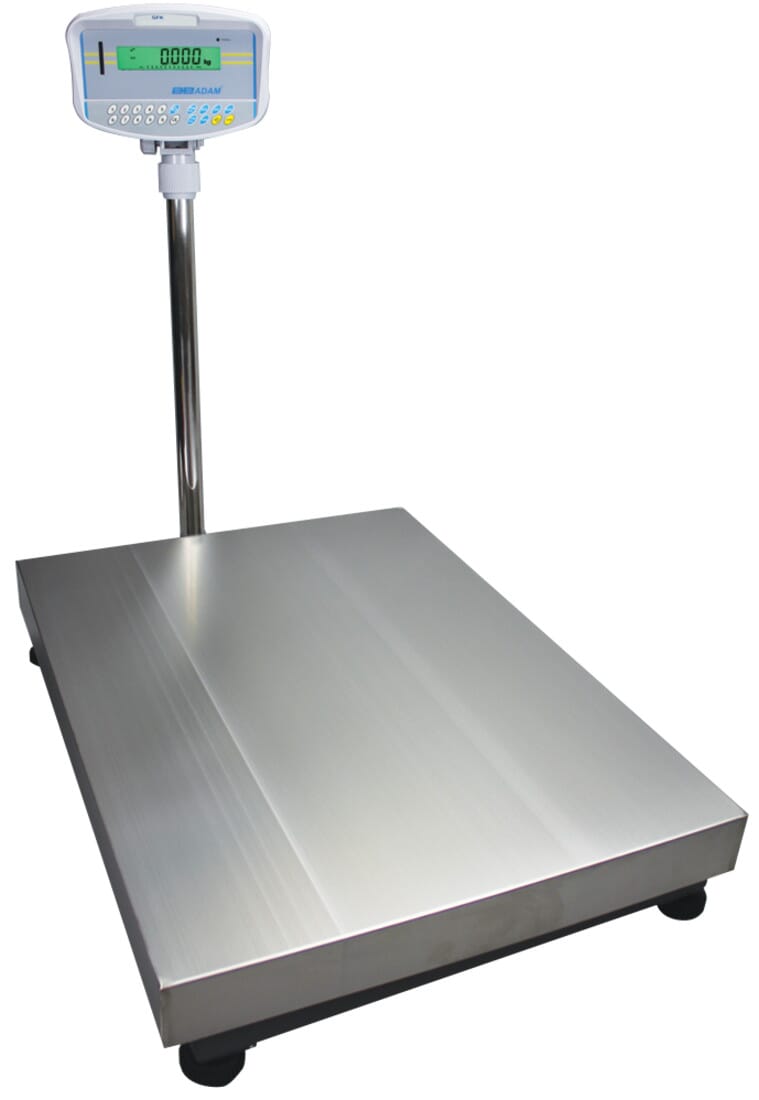

Industrial scales are essential tools utilized across various fields for exact weight dimension. One typical kind is the system scale, which supplies a large weighing surface area perfect for bulky and hefty products.

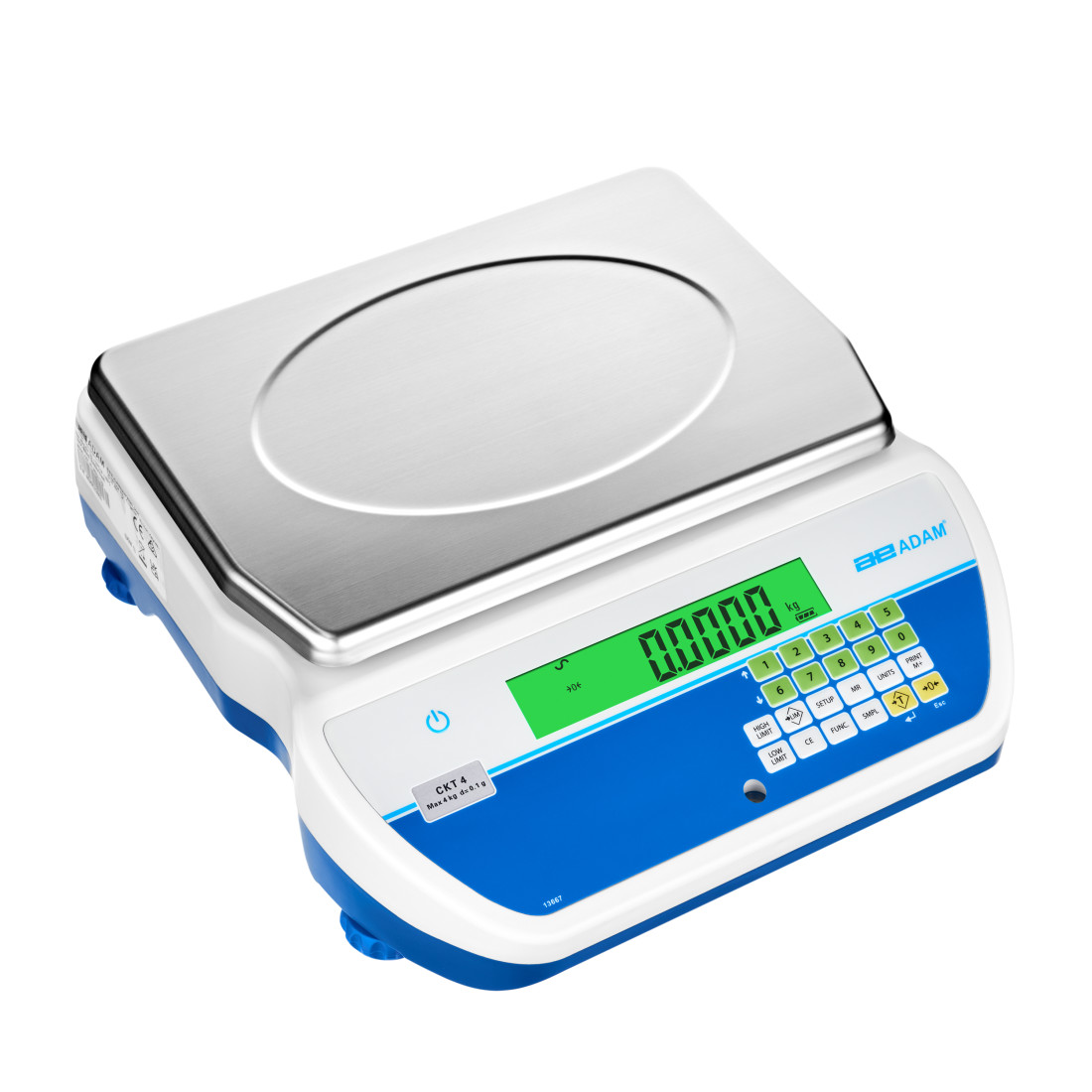

One more prevalent kind is the bench scale, which is appropriate and portable for smaller products. These ranges are frequently found in retail and food service settings, where fast and accurate dimensions are essential. Flooring ranges serve a similar purpose however are made for sturdy applications, enabling the evaluating of big pallets and containers straight on the ground.

Furthermore, electronic scales have actually gotten popularity as a result of their convenience of use and accuracy. They frequently feature sophisticated electronics that improve capability, such as connectivity alternatives for data tracking. Additionally, portable ranges use versatility for on-the-go evaluating, making them indispensable in areas like farming and logistics.

Comprehending the various kinds of industrial scales is vital for picking the ideal tools to meet particular operational needs, making sure performance and precision in weight dimension.

Key Functions of Industrial Scales

When choosing the ideal type of commercial range, it is essential to take into consideration the vital attributes that improve their functionality and viability for details applications. One of one of the most vital features is the scale's capacity. Industrial scales are available in various weight abilities, ensuring that they can accommodate the demands of different sectors, from light materials to hefty lots.

One more essential feature is precision. High-precision tons cells are essential for guaranteeing that measurements are trustworthy and consistent, which is vital for supply management and quality assurance. Furthermore, the readability of the display screen plays a considerable role; clear, electronic displays with adjustable illumination enable very easy viewing in various lighting conditions.

Sturdiness is an additional vital characteristic, with several industrial scales designed to endure extreme atmospheres, consisting of exposure to moisture, chemicals, and hefty usage. Some models also feature stainless-steel or water-proof construction. Connectivity options such as Bluetooth or USB enable seamless information transfer and assimilation with various other systems.

Benefits for Office Effectiveness

Efficient workplace operations can substantially profit from the assimilation of industrial scales, as they enhance processes and boost efficiency. By supplying accurate weight dimensions, commercial ranges remove the capacity for human error, making certain that materials are weighed go to my blog continually and precisely. This accuracy is vital for stock management, lowering waste and decreasing costs connected with over-ordering or underutilization of materials.

Moreover, industrial scales allow faster processing times. With automated weighing remedies, employees can promptly acquire weight data without hand-operated estimations, maximizing time for other essential jobs. This velocity in operations not only improves functional efficiency yet additionally helps meet manufacturing target dates extra properly.

In addition, commercial scales provide valuable information that can be evaluated for continuous enhancement. By monitoring weight patterns, companies can identify inefficiencies in their processes news and apply rehabilitative actions, inevitably leading to enhanced performance.

The combination of these ranges also supports compliance with industry laws, as precise reporting of weights is typically required. This lowers the threat of expensive fines and boosts the business's reputation for reliability. Industrial Scales. Overall, the unification of commercial ranges adds to a more effective, cost-effective, and certified workplace atmosphere

Applications in Different Industries

The convenience of industrial ranges enables them to play a vital role throughout a plethora of sectors, enhancing functional capacities in varied applications. In manufacturing, accurate weight dimensions are vital for high quality control and stock management, making certain that items fulfill requirements and minimizing waste.

In the food industry, industrial ranges are made use of for section control, recipe formulation, and conformity with health laws, guaranteeing food security and consistency. In the pharmaceutical field, exact considering is necessary for medicine formulation, where also small disparities can lead to considerable governing issues and safety issues.

Construction and logistics industries likewise profit from commercial scales, as they assist in taking care of resources and enhancing delivery procedures. By providing accurate weight data, these scales promote far better tons preparation and conformity with transport regulations.

Additionally, the farming market utilizes commercial scales for considering fruit and vegetables, livestock, and feed, therefore enhancing functional effectiveness and ensuring reasonable profession methods.

Upkeep and Calibration Tips

To guarantee optimal performance and long life of commercial ranges, routine maintenance and calibration are vital. Operators should regularly clean the range to prevent debris accumulation, which can affect precision.

Calibration is equally crucial; it makes sure that the range offers accurate analyses according to sector standards. It is advisable to calibrate scales on a regular basis-- at the very least as soon as a year or more regularly if the scale is used heavily or relocated regularly. Adhere to have a peek here the supplier's standards for calibration procedures, which frequently include using qualified calibration weights.

Additionally, maintaining proper ecological conditions, such as temperature level and moisture control, can enhance scale efficiency and accuracy. Last but not least, training team on appropriate usage methods will certainly even more protect versus misuse that could lead to errors or damages. By sticking to these maintenance and calibration tips, businesses can guarantee their commercial scales run effectively, ultimately sustaining efficiency and compliance with governing requirements.

Conclusion

In recap, commercial scales function as essential instruments for enhancing workplace efficiency across varied sectors (Industrial Scales). Their high ability, precision accuracy, and resilient building add to ideal operations and top quality control. The integration of advanced attributes, such as digital displays and information connection, additionally reduces human mistake and supports governing conformity. By recognizing the crucial functions and advantages of commercial scales, companies can leverage these tools to boost material application, decrease waste, and inevitably drive productivity.

Industrial ranges are pivotal in improving functional performance throughout various markets, supplying features such as high capability, precision accuracy, and durable building.When selecting the proper kind of commercial range, it is vital to take into consideration the essential functions that boost their capability and viability for specific applications. By supplying precise weight dimensions, commercial ranges remove the potential for human mistake, making sure that materials are weighed consistently and precisely. It is a good idea to adjust scales regularly-- at least when a year or more often if the range is used heavily or moved frequently. By understanding the essential features and advantages of commercial ranges, companies can take advantage of these devices to enhance material utilization, reduce waste, and ultimately drive performance.